Cuttle now open for sign ups 🚀 - plus "Read Me" pages 📄 and more

Hi everyone,

Cuttle is now open for sign ups!

Cuttle is a design tool for digital cutting machines. It combines the familiar interface of a vector editor (like Illustrator or Inkscape) with precision, live modifiers, parameters, and scripting.

We’ve been in private beta the past year but are now excited to welcome anybody who’d like to give Cuttle a spin! Sign up if you haven’t already 🙌

Here are the updates for this week:

“Read Me” Pages 📄

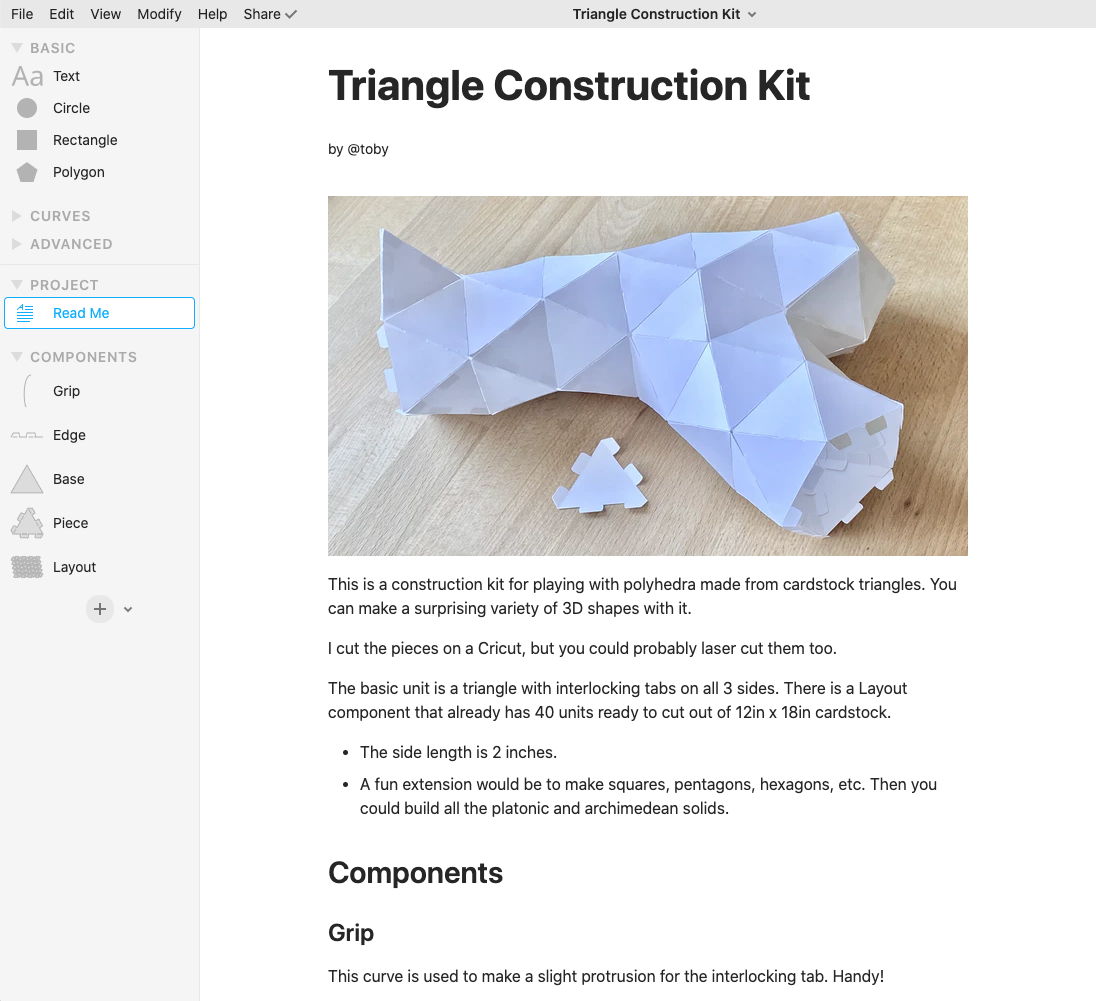

There’s now a space to write documentation for your projects. Click “Read Me” in the left sidebar.

The “Read Me” is a handy space for writing notes. You could write about:

- Materials and cut settings

- Assembly instructions

- What your project parameters do

- Things you learned along the way

- Next steps for the project

You can also upload images!

Here’s an example “Read Me”: this Triangle Construction Kit consists of triangular pieces with interlocking tabs. You can cut out a bunch from cardstock and build a surprising variety of 3D shapes.

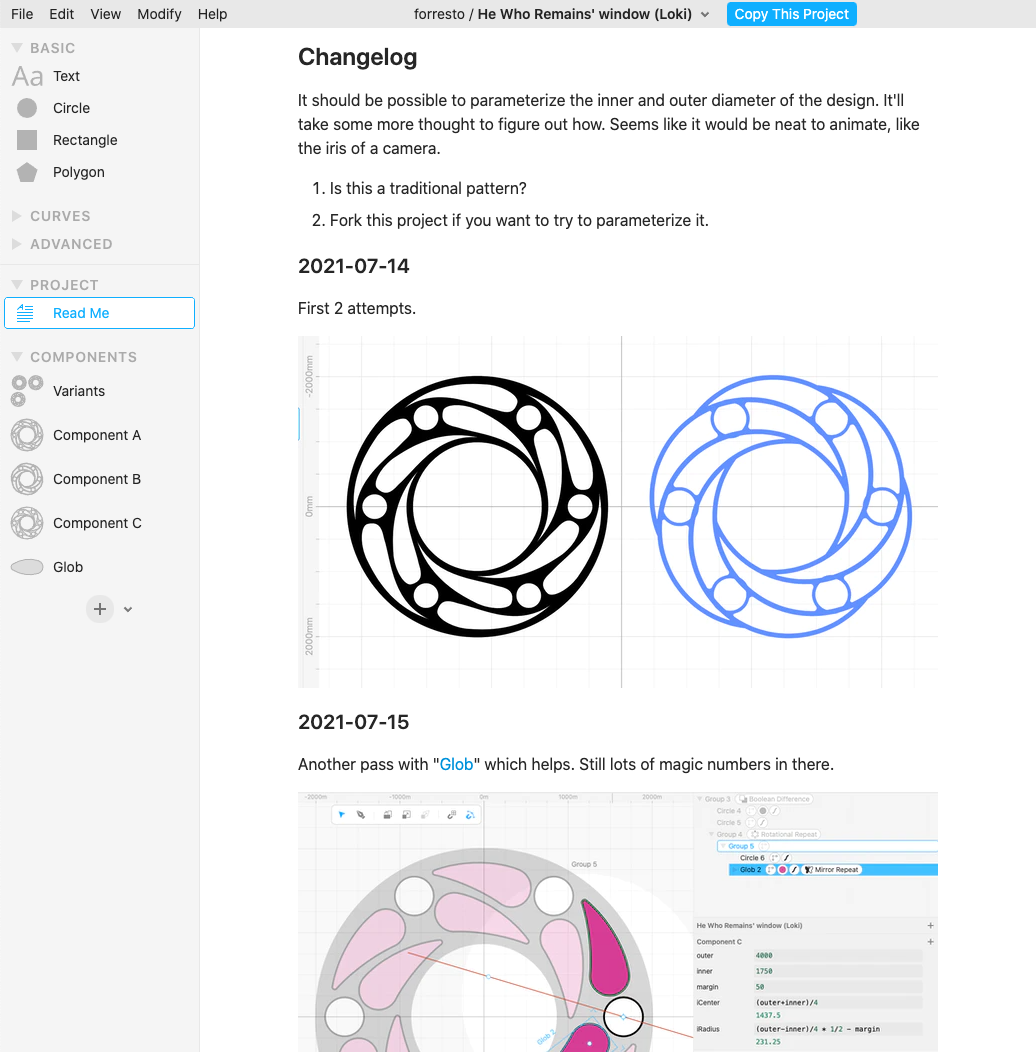

You can also use the “Read Me” as a project diary, to keep notes on your design iterations. Here’s an example from Forrest.

Thank you to users @tommallama and @aohnstad for suggesting that we add a documentation area. And thank you to the many users who “hacked” this with Text, showing us the way.

Let us know what features we should add to make the “Read Me” area more useful for you. Video embeds?

Better Box Select

When you drag on the canvas background it makes a “box selection” — anything that touches the box gets selected.

Now you can hold the option / alt key to only select the shapes fully contained within the box. This can be useful when selecting lots of small, overlapping shapes.

Fixed Expand and Contract

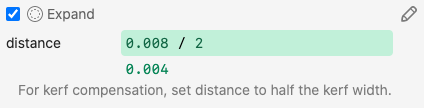

We fixed a bug where the Expand and Contract modifiers were only expanding and contracting by half the distance you put in.

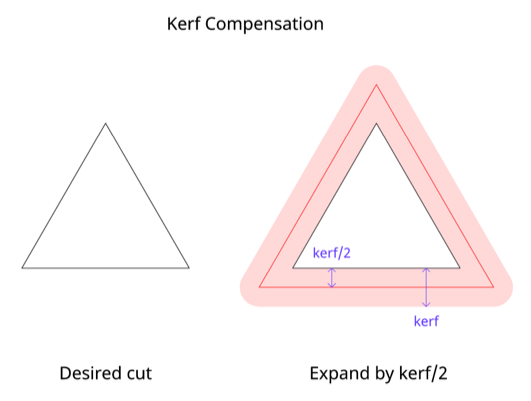

One note: if you’re using Expand for kerf compensation, you should enter in half the kerf width.

For a laser cutter, a typical kerf width is .008 inches, so in that case you would use .008 / 2.

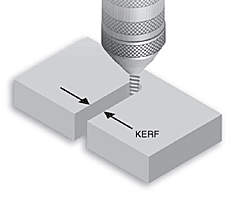

Wait, what’s “kerf”? The kerf is the width of material that is removed by a cutting process.

Kerf width depends on the cutting process (a router takes out more material than a laser), the material, thickness, and cut settings.

For a laser cutter, kerf is usually negligible unless you’re trying to get pieces to fit together just right, for example press-fits and inlays. In those cases you’ll want to compensate for the kerf by expanding by half the kerf width.

Design improvements on the Project Dashboard

We cleaned up the top navigation bar on the dashboard. There are now links to helpful resources in the upper-left corner.

The Tutorials page has links and descriptions for all of the video tutorials on our YouTube channel.

Other Improvements and Fixes 🐞

- Shapes and Modifiers are colored red in the outline when they contain an error.

- Pen tool is more accurate when holding shift to align to the previous anchor.

- Snapping from a geometry point to a grid point is more accurate.

- Using the arrow keys to nudge a shape will nudge in grid increments when grid snapping is on.

- Fixed a bug that could cause the constraint axis to jitter when holding shift.

- Strokes with “outer” alignment are now correctly rendered in PNG export and thumbnail images.

- Redesigned the “footer” on all Cuttle pages.

- Behind the scenes, upgraded our database.

Thanks for sticking with us as we build Cuttle! As always, I love to hear your feedback — reply to this email or chat with us on the Discord chat room.